Mobile Crusher Plant

Mobile crusher plant combines several equipment components into a single unit, which enables efficient and flexible operations in various locations. It is designed for crushing various types of materials on-site , such as rocks, ores, and construction waste, into smaller sizes for further processing or recycling.

Tire or Crawler Type

50-500tph

Good Helper for on-site Work

1.jpg)

Hot-sale Mobile Crushing Plant – 4 in 1 Unit

We have launched the widely popular OTX4 mobile crushing and screening integrated machine, which is a masterpiece in the field of mobile hard rock crushing and screening. It integrates four units, namely the vibrating feeder, jaw crusher, multi-cylinder hydraulic cone crusher and three-layer double-stage screen. Through ingenious structural design, it has achieved the crushing and screening effects of a split hard rock production line, making it highly suitable for various application scenarios in the construction and mining fields. With its mobility and high productivity, with an output of 200 – 400 tph, it can ensure that you can use it easily at different construction sites.

OTX4 - Integrated Machine of Jaw Crusher, Cone Crusher and Screening

- Capacity: 200-400tph

- Configuration: vibrating feeder, jaw crusher, cone crusher and vibrating screen.

- Finial Particle Size: 0-5mm, 5-10mm, 10-20mm, 20-40mm etc

- Main Application: Suitable for secondary and tertiary crushing and screening of medium to high hardness materials, hard rock line production in tight spaces, crushing and sand-making of highly wear-resistant stones like quarry river pebbles, granite and diabase (with SiO₂ > 75%), and pre-ball milling crushing of iron ore in large beneficiation plants.

| MODEL | OTX4 |

| Feeder | |

| Feeding height(mm) | 4100 |

| Feeder width-length(mm) | 1100*3737 |

| Power(kw) | 2*3.7kw |

| Return screen(double segment) | |

| Layer number of mesh | 3 |

| Vibrating screen width-length(mm) | 2000*2500/2000*3500 |

| Power(kw) | 4*6kw |

| Conveyor | |

| Main conveyor width*length(mm) | 1200*15500 |

| Finished material side conveyor width*length(mm) | 500*6125 |

| Under screen conveyor width*length(mm) | 1200*7570 |

| Return conveyor1 width*length(mm) | 1000*9760 |

| Return conveyor2 width*length(mm) | 1000*6260 |

| Parameters | |

| Total power(kw) | 452 |

| Processing capacity(t/h) | 200-400 |

| Speed(km/h) | 0.6-1 |

| Total Weight(t) | 115 |

| Transportation size(mm) | 20700*5100*4000 |

Mobile Crusher Plants With Different Chassis For Selection

According to the chassis type, there are two types of mobile crushing and screening plants for sale in AIMIX Group, including tracked type and wheeled type. Each type can be equipped with various crusher hosts, like mobile jaw crusher, mobile cone crusher plant, and mobile impact crusher plant.

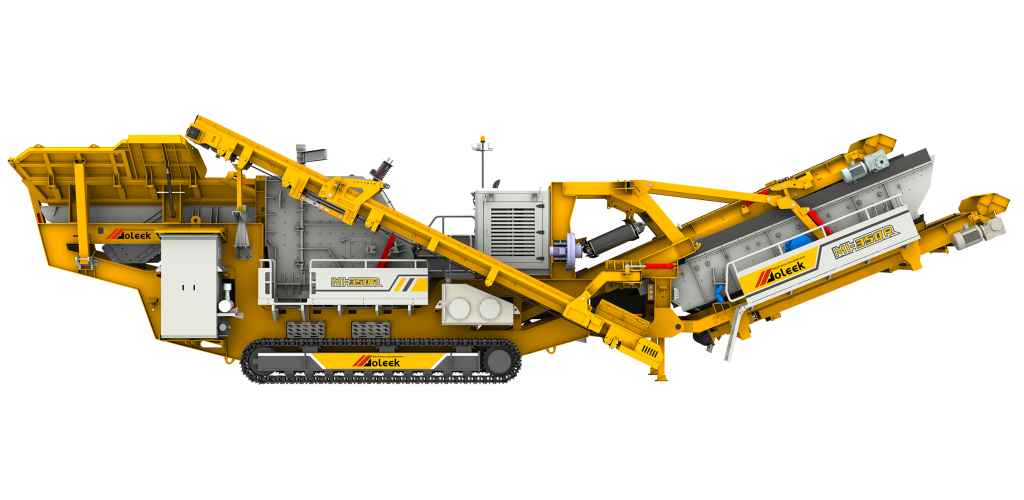

Impact Type Mobile Crusher Plants – Low Production Cost

The OLEEK OI series of Crawler Mobile Impact Crushing Plants feature compact and efficient modules. Hydraulic assistance is applied in multiple aspects. A return material screening system is added, and there are also iron removal, wind separation and spraying devices. It is suitable for the first and second crushing stages of medium and soft hardness materials, ore crushing in mines, construction waste recycling, production of construction aggregates, as well as highway/railway and road and bridge construction. The whole machine has stable performance, is convenient for relocation, and can produce good crushed particle shapes.

Feeding Size: ≤700mm

Capacity:

100-600T/H

Crusher Types: Impact

Finished Particle Size: 25-100mm

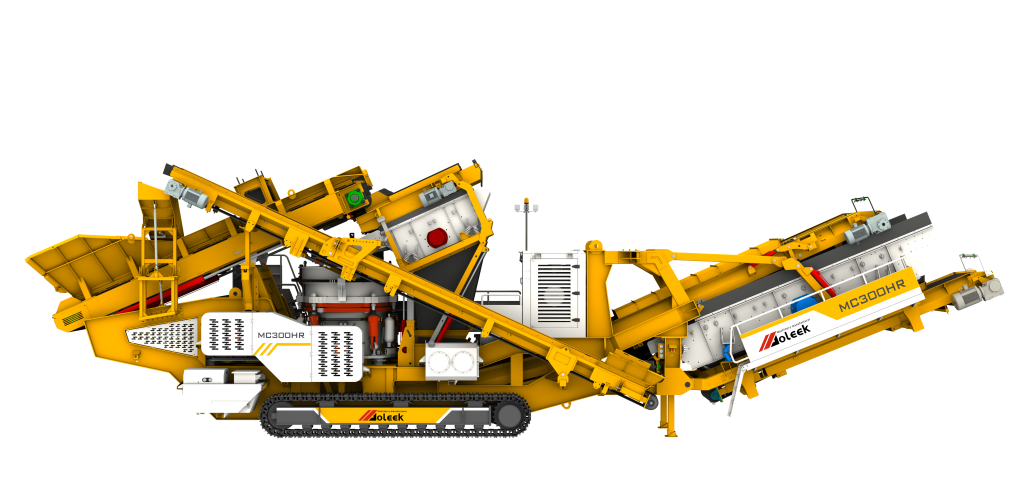

Cone-Type Mobile Crusher Plant – Secondary Or Tertiary Crushing

The OLEEK OC series of Crawler Mobile Cone Crushing Plants adopt multi-cylinder cones for the main machine, which realizes laminated crushing. And it is equipped with a large-torque retarder feeder to ensure uniform feeding. It is applicable to the secondary and tertiary crushing stages of medium and high hardness materials, the crushing and sand-making of highly wear-resistant stones (with SiO2 content higher than 75%) such as quarry river pebbles, granite and diabase, and the crushing before ball milling for iron ore in large-scale ore dressing plants. The whole machine is compact, convenient for relocation, has a large crushing output, low wear and high reliability.

Feeding Size: ≤300mm

Capacity:

150-495T/H

Crusher Types: Cone Crusher

Finished Particle Size: 0-45mm

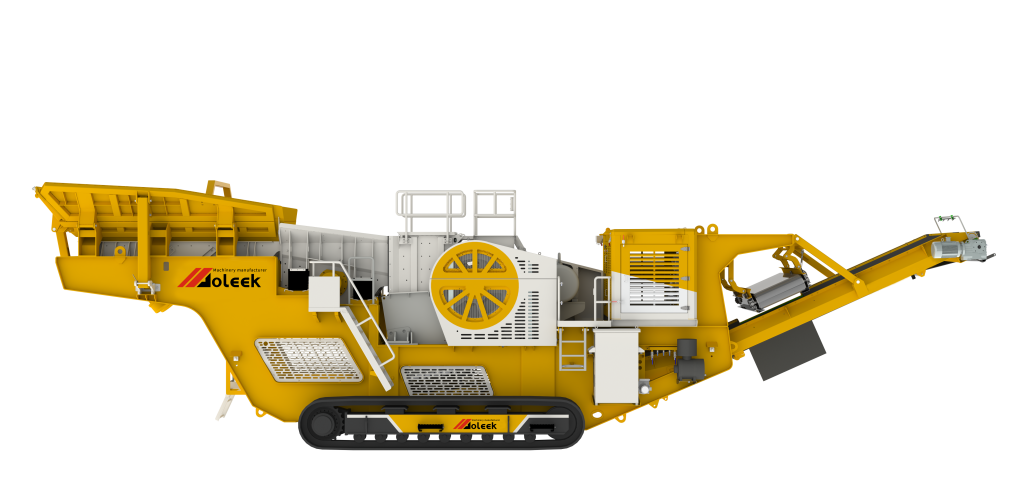

Jaw-Type Mobile Crusher Plant – Primary Crushing

The OLEEK OJ series of Crawler Mobile Jaw Crushing Plants are equipped with the European version C series crushing main units, oversized folding hoppers, and an independent pre-screening system is added. There are also iron removal and spraying devices. They are mainly used for the primary crushing of medium and high hardness materials, ore crushing in mines, construction waste recycling, production of construction aggregates, highway/railway construction, and road and bridge construction, etc. It is convenient for relocation and has high crushing efficiency.

Feeding Size: ≤600mm

Capacity:

80-570T/H

Crusher Types: Jaw

Finished Particle Size: 40-200mm

Crawler-Type – The First Choice For Construction Waste Recycling

Crawler mobile crush plant offers versatile solutions for various industries and applications. They are widely used in construction sites, allowing the on-site crushing of construction waste, reducing transportation costs, and promoting sustainable practices. The crawler crushers can transform demolished materials into reusable aggregates. The crushed aggregate from construction waste can be applicable in urban infrastructure development such as highways, railways, and tunnels, etc.

Feeding Size: ≤300mm

Capacity: 70-500T/H

Crusher Types: Impact

Finished Particle Size: 0-40mm

Multi-functional Mobile Crushing Strategies for Assorted Applications

In the current era, the requirement for multifunctional and high-efficiency crushing solutions has reached an unprecedented level. Choosing a suitable mobile crushing plant is of utmost importance for enhancing productivity and profitability, irrespective of the specific industry or application. The materials they can be applied to and the fields of application are detailed below:

- Applicable Material: Granite, basalt, limestone, quartzite, iron ore, copper ore, gold ore, construction debris, cement, asphalt, brick fragments, rubble pieces, glass shards, coal lumps

- Applicable Fields: Mining and quarrying undertakings, production of aggregates for concrete, asphalt, and roadway building, recycling of construction and demolition waste materials, chemical manufacturing, among others.

Subsequently, I will present to you several mobile crushing alternatives applicable on-site for your perusal.

50tph Mobile Crusher Plant For Sand and Aggregate Production

- Processing capacity: 200tph

- Output size: 0-20mm

- Applications: crushing river stones for sale of sand and aggregate materials

Configurations:

vibrating feeder + a jaw crusher + a cone crusher + vibrating screen+ belt

200tph Mobile Jaw Crusher Machine For Road Construction

- Processing capacity: 200tph

- Output size: 0-20mm

- Applications: crushing river stones for sale of sand and aggregate materials

Configurations:

vibrating feeder + a jaw crusher + a cone crusher + vibrating screen+ belt

200tph Crawler Mobile Concrete Crushing Plant Processing Construction Waste On-site in Malaysia

- Processing capacity: 200tph

- Output size: 0-20mm

- Applications: crushing river stones for sale of sand and aggregate materials

Configurations:

vibrating feeder + a jaw crusher + a cone crusher + vibrating screen+ belt

The versatility of mobile crushing solutions is essential in meeting the diverse needs of various industries and applications. The above mobile crushing solutions are all over 100 tph, larger-scale crushing projects. If your project is relatively small, never mind, AIMIX also manufactures small size mobile crushing and screening equipment to meet your crushing demands.

Small Mobile Crushing Plant Suitable for Your Projects – 30~50 tph

AIMIX is proud to customized the crushing solutions that are appropriate for efficient and effective small-scale crushing tasks. If your budget for starting mini mobile crusher plant business is limited, it will be your best choice. With options for both crawler and wheeled types, the small mobile crusher plant is versatile and adaptable to a variety of working environments.

How Does A Mobile Crushing Plant Work?

The mobile crushing plant consists of several components, like crushers, feeders, and screens. These key components work in harmony to crush and screen materials on-site. Here is an overview of how the mobile crusher plant work:

The mobile crushing plant is transported to the job site and set up. Its mobility allows it to be moved closer to the material source.

Raw materials are fed into the feeder, which regulates the amount of material entering the mobile crusher.

The material is crushed in the crusher, where it is broken down into smaller pieces. The type of crusher machine used will determine the final size and shape of the material.

After crushing, the material may go through a screening process to separate it into different sizes. Oversized materials can be sent back for further crushing.

The processed material is then discharged onto conveyor belts or directly into trucks for transport.

5 Reasons To Choose Mobile Crusher Plant from Us

Strong Ability To Adapt To Application Scenarios

The AIMIX mobile crusher plant for sale is designed to have a compact and space-saving footprint, making it suitable for both urban and remote areas. It comes with integrated features such as a vibrating feeder, pre-screening system, and conveyor belts, which enhance the overall efficiency and productivity of the crushing process.

Good Safety

Mobile crusher plants prioritize safety with features like hydraulic release mechanisms to prevent damage from uncrushable materials and emergency stop buttons for quick shutdown in case of emergencies.

Strict Quality Control

Mobile crusher plants prioritize safety with features like hydraulic release mechanisms to prevent damage from uncrushable materials and emergency stop buttons for quick shutdown in case of emergencies.

Easy Maintenance

Mobile crusher plants prioritize safety with features like hydraulic release mechanisms to prevent damage from uncrushable materials and emergency stop buttons for quick shutdown in case of emergencies.

Original Wearing Parts Supply

In order to ensure the safe and smooth operation of the customer’s mobile crushing plant, considering the degree of wear and tear, our company specially provides our customers with high-quality original wearing parts supply, to solve the customer’s worries.

Clearly understanding each one is the basis of choosing a right mobile crusher plant. But how can you choose the right mobile crushing plant? The semi mobile crushing plant price is important and needs to be focused on, but investing in one isn’t just limited to writing down the semi mobile crusher price. You need to carefully consider all the matters involved before, during and after the choice, and then go to negotiate with the mobile crushing plants supplier in order to get twice the result with half the effort.

Here are a few suggestions for you to choose the mobile crushing & screening plant.

How to Choose A Right Mobile Crushing Plant?

01

Specify Your Needs.

First, you need to determine your needs, you need to know clearly what kind of project you are buying this mobile crusher plant for because there are more kinds of mobile crushing plants, different kinds also have different fields of application, so you must contact your engineer to negotiate your needs before asking for a quotation.

02

Know The Capacity.

Capacity is a very important factor, which is not only related to the production capacity of the portable crusher plant but also closely related to the price of the mobile crushing plant. Theoretically, the larger the capacity of the machine, the higher the portable crusher price will be. To avoid waste, just tell us your production requirements and we will recommend suitable portable crushing plant for your project.

03

Determine Right Mobile Crusher Manufacturers.

Choosing the right mobile crushing plant manufacturer is crucial for quality, customization, support, and compliance. Reputable mobile crushing plant manufacturers ensures reliable, durable plants with customization options to meet specific needs. They provide technical expertise, after-sales service, and spare parts availability. Compliance with safety and environmental regulations is assured.

Knowing how to choose the right mobile crushing plant, I believe you already have a choice of your favorite mobile crusher and screening plant in mind. The next step is to consider the mobile screening plant price, so many mobile crusher plant manufacturers on the market, how can we talk about a reasonable price?

3 Tips To Help You Get A Reasonable Quote!

Everyone is the same, the first thing you do when buying something is to ask for a quote, while the mobile crusher plant price in turn is absolutely related to many factors, such as the location of the project, the type of product, and the size of the venue.

Therefore, before you want to be subject to specific prices, the user needs to figure out the things mentioned above. If possible, you can also write down the project local climate conditions, air pressure, voltage, etc., the more detailed, we can provide an accurate program to determine which product, which configuration is suitable for your project. Here are a few steps to help you inquire about the most real and accurate mobile screening plant price.

Find a Reliable Mobile Crusher Plant Supplier

This is the first important thing, the stone mobile crusher plant belongs to large equipment, if you find a mobile crush plant supplier, the quality of thestone crushing plantsand the follow-up service can not be guaranteed. So you need to search Google, find more than 5 suppliers of mobile crushing machine, and make a strict and careful comparison.

Visit The Factory

After you have found several mobile crushing unit suppliers, the next thing you need to do is to examine the qualifications and capabilities of these mobile crusher machine suppliers. If possible, it is best to visit the factory, from the size of the vendor, staff, production technology, testing, shipping, etc. can determine the reliability of the vendor.

Multiple Negotiations

After visiting the plant, you will definitely have a choice in your mind, when start talking about thecrusher plant price AIMIX, you have to understand the composition of this quotation from multiple angles, such as production technology, materials used, patents, after-sales service, etc., from these aspects to measure whether this mobile crushing plant meets your expectations, the most important thing is to look at their previous customer feedback, the real feedback on this product is the most important thing, objectively demonstrates the performance of the mobile crusher plants for sale.

After these three steps, you will surely find the right portable crusher plant for your project, and you will also get a good offer.

But the investment of the portable crusher plant is not simply buying and operating the portable crushing and screening plants, besides these, there are also maintaining the product, exploring more possibilities of the product and so on.

Therefore, we not only need to pay attention to the offer of this mobile crushing plant, but also you need to consider the following things in order to make the investment in mobile crushing plant more money.

Maximize The Benefits Of Investing In Mobile Crushing Plant

Everyone is the same, the first thing you do when buying something is to ask for a quote, while the mobile crusher plant price in turn is absolutely related to many factors, such as the location of the project, the type of mobile crushing station, and the size of the venue.

Seek diversified market opportunities:

In addition to the regular building and road construction market, seeking market opportunities in other areas can increase profits. Consider cooperating with related industries, such as quarries, waste recycling and earthmoving, to broaden the scope of application of products and improve portable crusher plant utilization. If necessary, you can also consider the option of selling the portable crusher plant at the end of the project or renting it out to someone in need. This is also a gain.

Pay attention to market trends and technological innovation:

Pay close attention to industry trends and technological innovation. Keep abreast of the latest mobile screening and crushing equipment technology and equipment improvements to stay competitive and meet customers’ changing needs. Upgrade equipment and introduce advanced technology at the right time to improve production efficiency and product quality.

Establishment of partnership:

Build good partnership with suppliers, customers and other stakeholders. Explore business opportunities together, share resources and experiences, and work together to maximize mutual benefits.

In short, the more information you give, the more accurate the solution we give and the more detailed the price will be. And you will get many benefits after using the mobile crushers and screeners. If you are looking for a cost-effective mobile crusher station, contact us we can provide you with a free proposal according to your project needs.

In addition to mobile crushing plant, fixed crushing plant is also a product often asked by customers, the following briefly popularize fixed crushing plant to you.

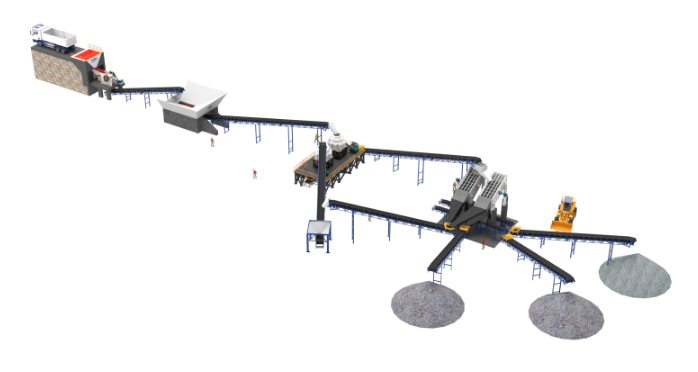

Related Products – Stationary Crushing Plant

Anyone who understands the crushing industry probably knows that in addition to mobile crushing trucks, engineers usually analyze the customer’s needs and combine jaw crusher, cone crusher, impact crusher, feeding equipment and screening system to form a set of inconvenient “stationary” crushing plant. Here we see what is the difference between stationary and mobile crushing plant.

- What Are The Differences Between Stationary And Mobile Crusher Plant

1. Mobility

The AIMIX mobile crusher plant for sale is designed to have a compact and space-saving footprint, making it suitable for both urban and remote areas. It comes with integrated features such as a vibrating feeder, pre-screening system, and conveyor belts, which enhance the overall efficiency and productivity of the crushing process.

2. Setup And Installation

Mobile crusher plants prioritize safety with features like hydraulic release mechanisms to prevent damage from uncrushable materials and emergency stop buttons for quick shutdown in case of emergencies.

3. Operational Flexibility

Mobile crusher plants prioritize safety with features like hydraulic release mechanisms to prevent damage from uncrushable materials and emergency stop buttons for quick shutdown in case of emergencies.

4. Production Capacity

Mobile crusher plants prioritize safety with features like hydraulic release mechanisms to prevent damage from uncrushable materials and emergency stop buttons for quick shutdown in case of emergencies.

5. Infrastructure Requirements

In order to ensure the safe and smooth operation of the customer’s mobile crushing plant, considering the degree of wear and tear, our company specially provides our customers with high-quality original wearing parts supply, to solve the customer’s worries.

It’s important to note that these differences may vary depending on specific models and configurations of crusher plants. The choice between stationary and mobile types depends on factors such as project duration, mobility needs, production requirements, and site conditions.

If you are interested in the stationary crushing plant, you can browse the following programs we have done for our customers.

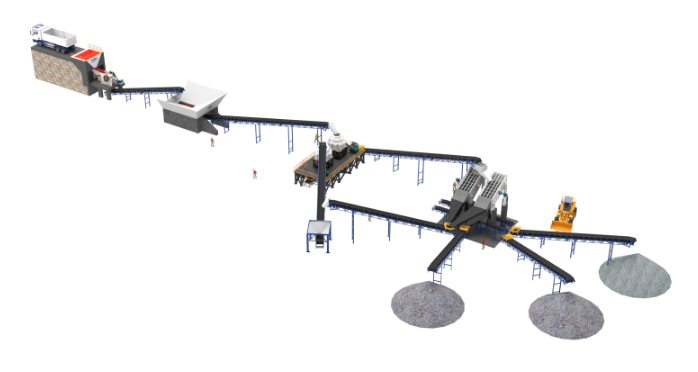

150TPH Stationary Crusher Plant For Concrete Production

Configurations:

APG-3895W (vibrating feeder)

APJ-6090E (jaw crusher)

APC-132C-M (medium crushing compound cone crusher)

APC-132C-F (fine crushing compound cone crusher)

APS-2160Y4 (vibrating screen)

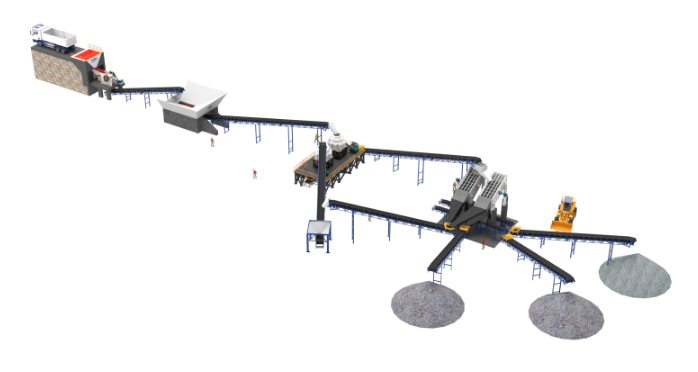

150TPH Stationary Crusher Plant For Concrete Production

Configurations:

APG-3895W (vibrating feeder)

APJ-6090E (jaw crusher)

APC-132C-M (medium crushing compound cone crusher)

APC-132C-F (fine crushing compound cone crusher)

APS-2160Y4 (vibrating screen)

150TPH Stationary Crusher Plant For Concrete Production

Configurations:

APG-3895W (vibrating feeder)

APJ-6090E (jaw crusher)

APC-132C-M (medium crushing compound cone crusher)

APC-132C-F (fine crushing compound cone crusher)

APS-2160Y4 (vibrating screen)